Product Development

Supertek stands for innovation and solutions in product development. While we have established ourselves as a leading provider in winding technology, our expertise extends far beyond this area. We develop high-quality machines, systems, and components specifically tailored to the needs of our customers in various industries.

Our Approach to Product Development

Our product development is based on close collaboration with our customers and a deep understanding of their specific requirements. Whether it involves custom winding machines or other specialized applications, our approach is always focused on innovation, efficiency, and the highest quality.

-

Needs Analysis and Consulting

Every successful product begins with a clear vision. At Supertek, we start our development process with a detailed analysis of our customers' requirements and goals. We take the time to understand your challenges and provide you with innovative solutions that excel in both winding technology and other industrial applications. -

Innovative Concept Development

Building on a thorough needs analysis, our engineers and technicians develop concepts based on cutting-edge technologies and proven practices. We place special emphasis on meeting our customers' technical and economic requirements, whether in manufacturing complex winding machines or developing other automated systems. -

Production and Quality Management

Production takes place in our manufacturing facilities. Each phase of the production process is monitored through strict quality controls to ensure that our products meet the highest standards, whether it is a winding machine or another solution. -

Continuous Support

Our commitment does not end with delivery – we offer comprehensive support, training, and maintenance programs to ensure the long-term success of our products.

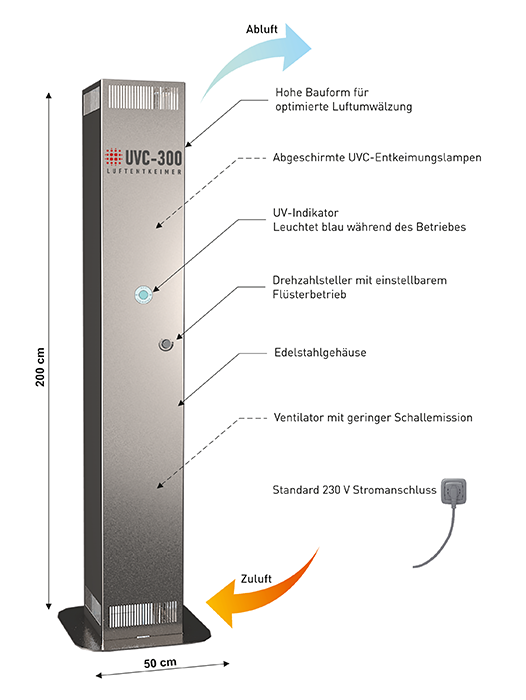

Product Development: Air Purifier UVC-300

Air Disinfection with Ultraviolet Light (UVC)

as a hygiene measure for enclosed spaces! www.uvc300.de

Supertek GmbH – More than Just Winding Technology

While winding technology is a core component of our portfolio, Supertek also provides solutions in the development and manufacturing of machines and systems for a variety of applications. Our flexible and innovative approach enables us to successfully implement projects across different industries, including automation, robotics, and other specialized industrial applications.

Development of a Fully Automatic Muesli Dispenser for Retail.

At Supertek, we have developed a muesli dispenser on behalf of our client that allows for the creation of customized muesli blends right on the spot. The dispenser is equipped with a robotic arm that retrieves a cup, brings it to the selected ingredients, opens the magazine lid, and dispenses each ingredient with precise gram measurements. After filling, the cup is sealed with a lid and labeled, making it easy to collect at the dispensing area.

Project-Based Product Development

We have developed a specialized ingredient magazine for retail that is used to fill muesli dispensers. Both the design of the magazine and the custom closure flap, manufactured using injection molding, are entirely developed by us.

Why Choose Supertek for Your Product Development?

- Extensive Expertise: In addition to our specialization in winding technology, we offer comprehensive experience in the development and manufacturing of machines and systems for a wide range of industrial applications.

Custom Solutions: We develop products that are perfectly tailored to the specific requirements and challenges of our customers.

State-of-the-Art Technologies: By using the latest technologies and high-quality materials, we provide products that are future-proof and competitive.

Comprehensive Service: From initial consultation through development and production to support, we offer a full-service experience that leaves no wishes unfulfilled.

Let’s Bring Your Next Project to Life

Are you interested in innovative product developments? Contact us today and let’s work together on your next successful project.

We also visualize the logistical integration of your systems and machines at the place of use, such as in your production hall, to ensure a smooth operation.