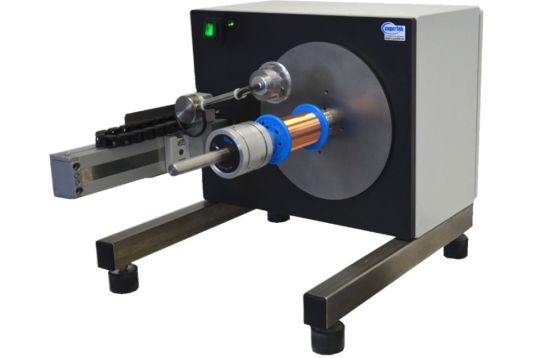

Coil winder

Supertek's automatic winders or take-ups consist of modular, intelligent units (smart winder units), they are compact, powerful and are ideally suitable for precise take-up or winding very thin, delicate wire, flat wire, glass fibre, fibre optic cables, fibres, silk, film, solder, filaments etc.

Winders or take-ups are available in different versions for different reels and reel sizes with rpm, speed, position and tensile force control.

Laying

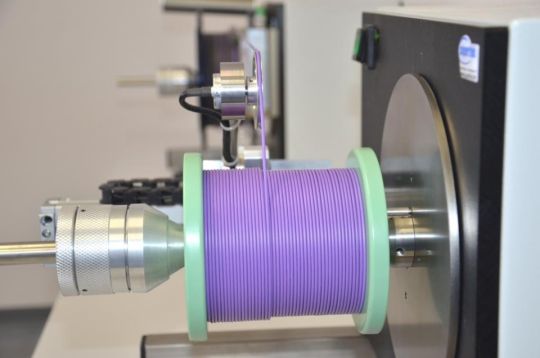

The main feature of a winder or take-up is laying the wound material, such as wire, on a spool provided for this. Different winding actions can be performed depending on the type of take-up:

- Incorporating and processing different types of spool, e.g. H spools, conical spools, air spools, customer-specific spools.

- Highly accurate laying, clean winding, flange detection, scanning the edge of the spool, level winding

- Positioning the wound material, precise determination of length or weight.

- Speed control (master) or tensile force control (slave)

| MW class take-up/ multiwinder |

|

| PTU class take-ups |

|

| Take-up winder for filament |

|

For many wound materials, e.g. for flat wires, tapes, films or for unwinding with short distances it is important that the product is always managed on one line. Winders with additional traversing spool drives, e.g. with the MW class multiwinders, can move the spool not only in a rotational movement but also in the axial (traversing type) direction so that the wound material can be wound in a fixed transfer position perpendicular to the spool.

For optimum laying it is necessary to synchronise the speed of the spool with the gradient of the laying machine.

Synchronisation may be performed, for example, by connecting the spool drive shaft mechanically to a rolling ring drive which converts the constant rotational movement of a smooth shaft into to and fro movements. One of the great advantages of rolling ring drives is, however, the inflexible parameter adaptation, especially during a spooling process. This includes adapting the laying inclination, the acceleration or adapting the switch-over points. For many winding processes mechanical laying with a rolling ring drive is no longer sufficient for today's technological requirements.

Supertek has developed its own fully electronic laying machine system to meet today's and tomorrow's high technological requirements for a winder or take-off. Based on studies in development projects, it has been established that synchronising spool speed and laying machine gradient with a constantly, unforeseeably changing spool speed with a familiar Programmable Logical System (PLC), cannot be implemented without a latency period. For this reason, Supertek has implemented the fully electronic laying machine system with an innovative microcontroller circuit with no measurable latency period. The advantages of a traditional mechanical connection and the advantages of an electronically adjustable system have been combined with the Supertek laying system.

With Supertek laying machines very accurate laying can be performed for different types of laying, materials and spool types.

Highly accurate tensile force or tensile stress control of the wound material can be achieved with the modular integration of the patented electromagnetic dancer, for example on the winder.

Multiple winder/ take-up

- Consisting of a basic frame and individual winder units

- Special designs or component solutions available

Several winder units with a flexible number can be fitted into a compact machine frame for multiple winders.

The winder can be operated via different HMIs using serial data communication.

Using Supertek's touch panel solutions with SUMMI PC-based software is a convenient solution for setting and monitoring the parameters.

Obviously, operation, monitoring, formula management and data saving can also be performed by another manufacturer's PLC or HMI, such as Siemens, Beckhoff or Allen-Bradley, etc.

Advantages of Supertek winders compared with traditional systems:

- Intelligent, modular units

- Digital specification of parameters, e.g. laying machine gradient, line speed, product length

- System can be networked, digital communication

- RPM, speed, position, length and, as an option, tensile force control can be selected.

- Highly accurate laying

- Digitally adjustable, high resolution laying parameters

- Increased quality, gentle, stress-free processing

- Ideally suited to the most delicate wires, fibres, glass fibre and other delicate wound materials

- Reproducible, digitally documentable laying control (track and traceability for consistent traceability of the line speed or laying parameters)

- Fully electronic system (no pneumatics or compressed air)

- Process-dependent adjustment of the laying possible at any time

- Suitable for dynamic processes

- Easy to integrate into existing and new machines

- Speed measurement

- Crack detection

- Short payback period

- Increased quality

Can be used as a winder, take-up, roller, shaft winder, reel, rewinder, multiple winder and can be used in annealing furnaces, dyeing plants, measuring devices, stranding machines, laboratory equipment, rewinding machines, winding machines etc.