Spool laying

|

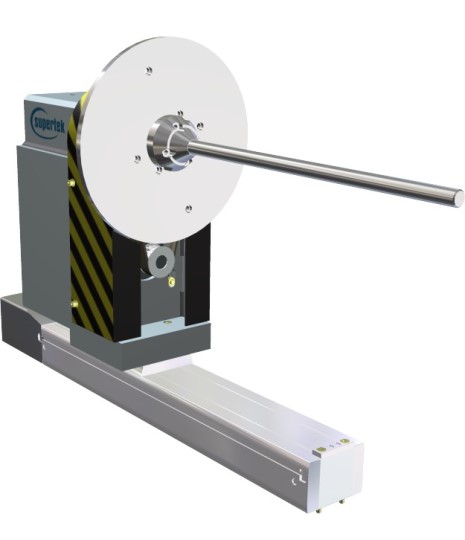

Supertek's automatic laying systems are highly accurate, programmable, fully electronic laying machines to load various types of wire, round wire, flat wire, fibres, tapes, filaments etc. onto different spools, H spools, conical spools, biconical spools etc. Supertek's laying systems can be used as a traversing spool drive so that the wound material can be wound at a fixed transfer position perpendicular to the coil. The product, such as flat wires, tapes, films etc. are run through the traversing laying systems always in one line. In combination with a contactless overrun control unit, the traversing laying systems are also ideally suited to straight line unwinding. Spool rpm and laying speed are synchronised by an innovative microcontroller circuit and high resolution drive motors without a measurable latency period in real time. Supertek's fully electronic laying systems always lay synchronously to the spool speed and guarantee a consistent laying gradient and a perfect laying appearance. All necessary parameters, such as start of winding, starting point, end of winding, end point, switch over points, laying gradient, laying appearance, dwell path etc. can easily be stored and implemented in a formula management system. With Supertek laying machines optimum winding appearance can also be achieved with automatic flange detection and permanent spool edge scanning even with high spool tolerances. Materials with fluctuating diameters, such as hoses, hollow wire, rubber, silicone hoses etc. can also be wound accurately over several layers with the sensor-supported Supertek laying systems. |

|

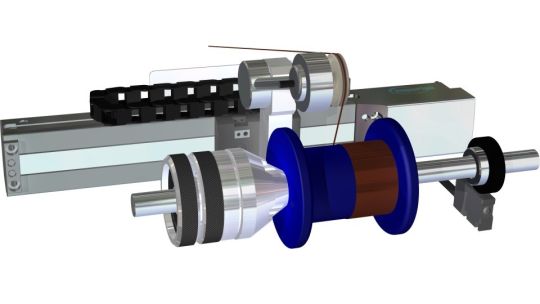

Electronic laying system ELU (PTU class) |

|

The electronic layer of Supertek is a highly precise processor-controlled linear drive for laying of wires and fibres on spools.

Used, for instance, in winders of PTU class. |

|

| CMC |

|

Quick and easy solution for adjusting tensile force and configuring the EDD.

Line display

Data communication very easy with RS485. |

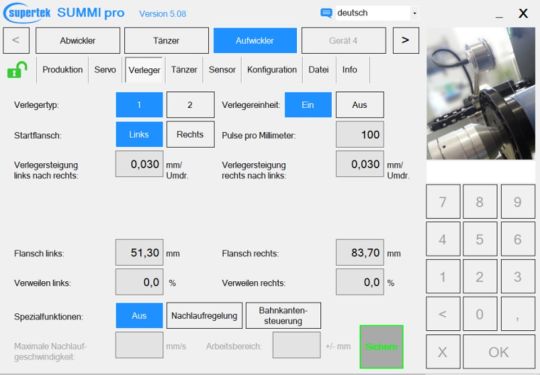

| Software SUMMI |

|

Professional setting on the touch display of the parameters among other things for winding with electronic publisher ELU or MCU.

Data communication with RS485 or USB. |